Fatigue tests at different speeds (cycles per minute) all along a range of mean loads are performed to determine the fatigue strength of a certain kind of metallic specimen. Such experiments involve expensive destructive tests and are therefore carefully designed and applied. Experiments where the fatigue test has been stopped prior to the occurrence of the specimen failure can also occur, leading to censored observations that are commonly called “run-outs”. We use statistical models specially tailored to analyze these kinds of data. A next crucial point is how to estimate the reliability fatigue life of the specimen and, in particular the unknown fatigue limit parameter of stress.

To this end, we provide a rigorous statistical framework to support making engineering decision for model calibration, Bayesian model selection and validation. Such approach is generalized to other kind of reliability data.

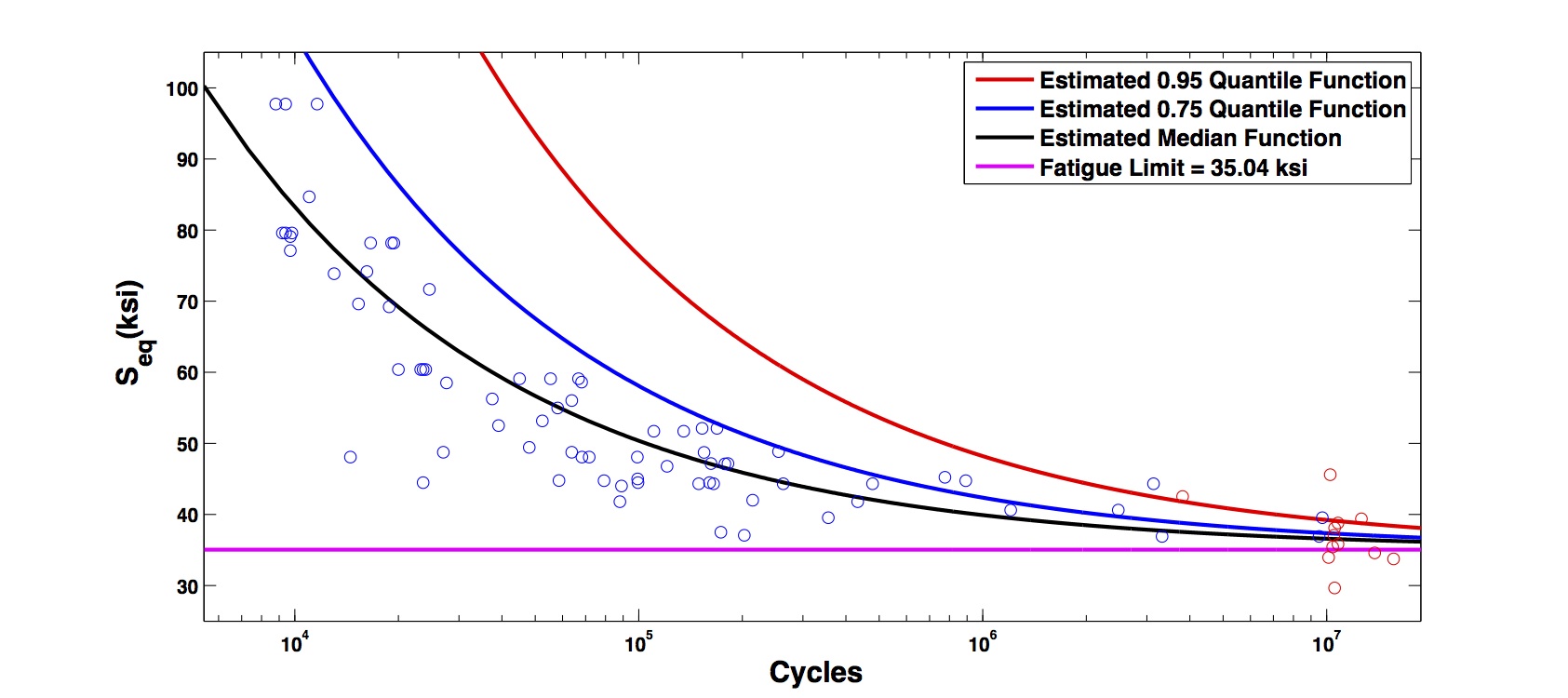

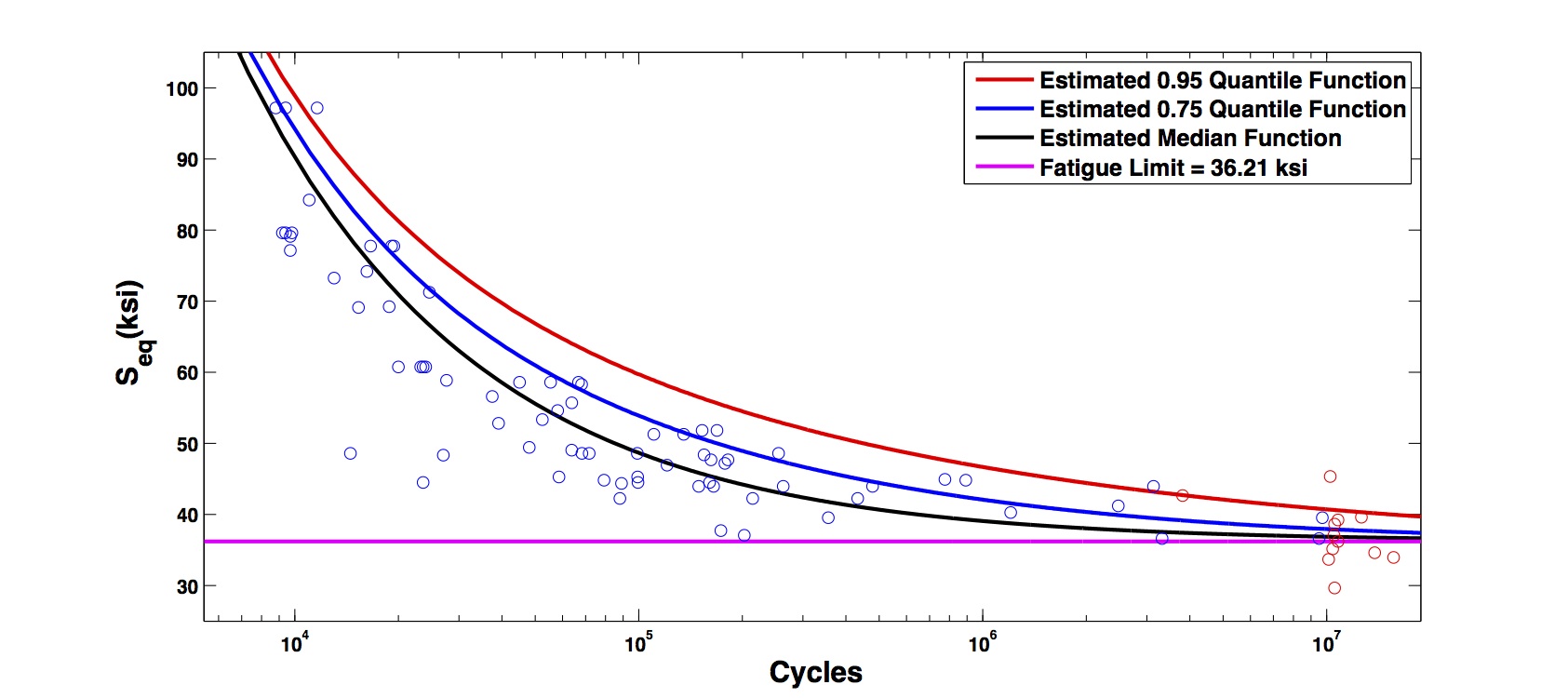

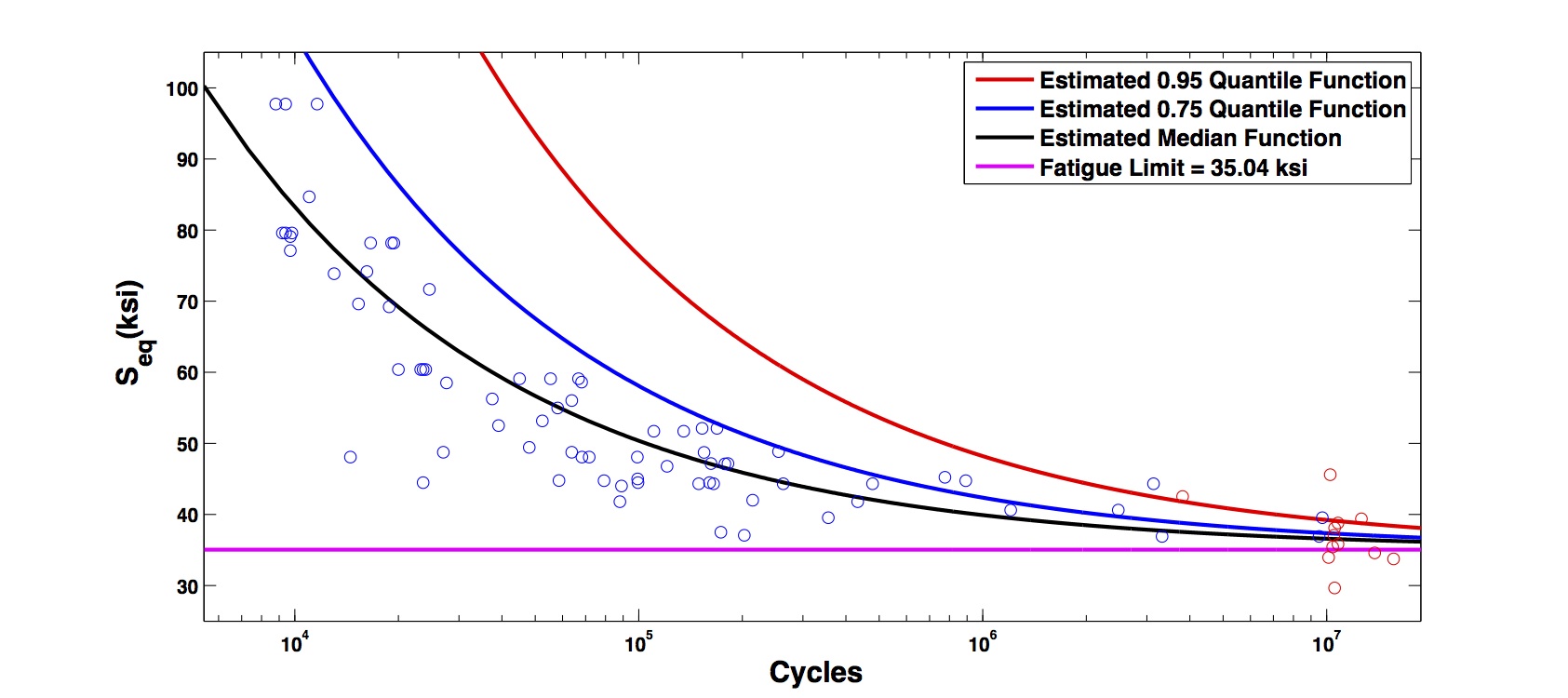

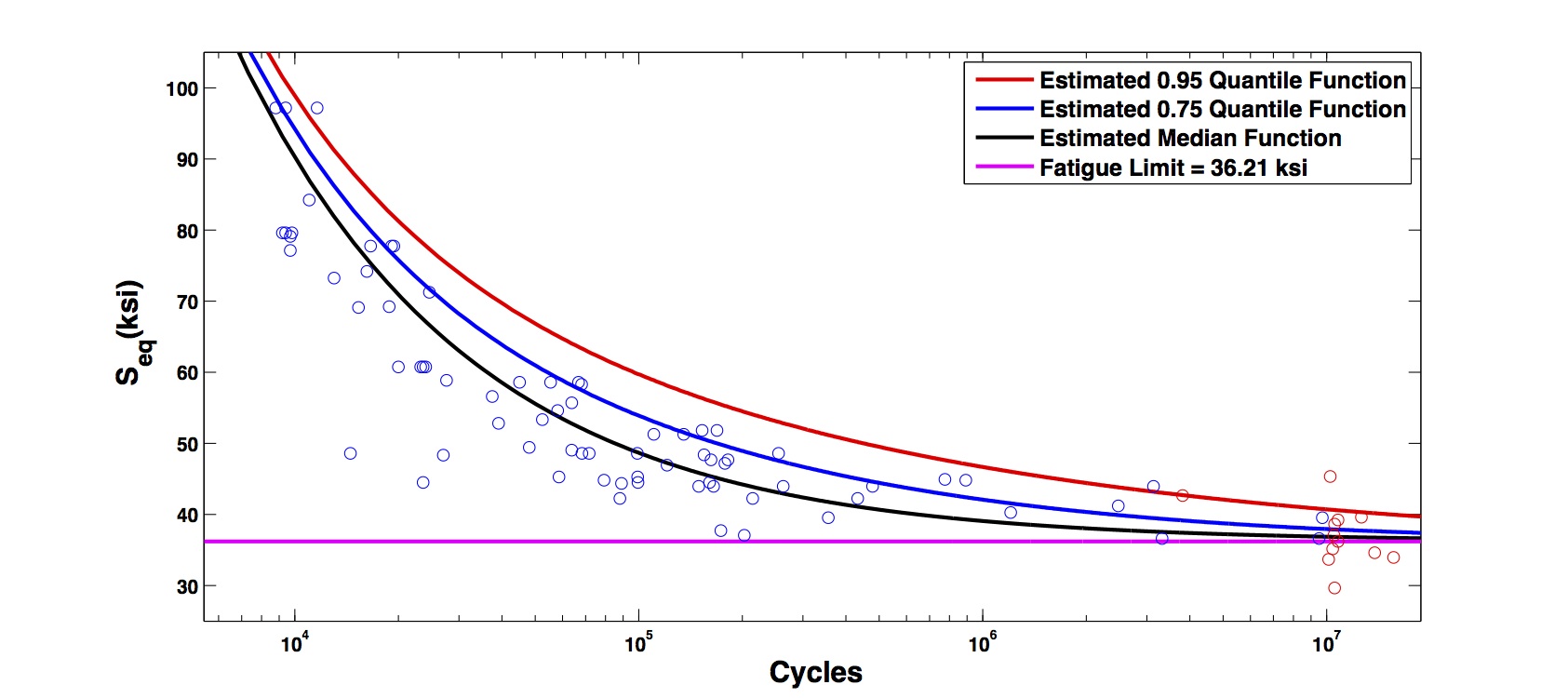

Calibration of models for censored metallic fatigue data with constant (left) and nonconstant (right) standard deviation:

quantile functions and fatigue limit parameter estimates.

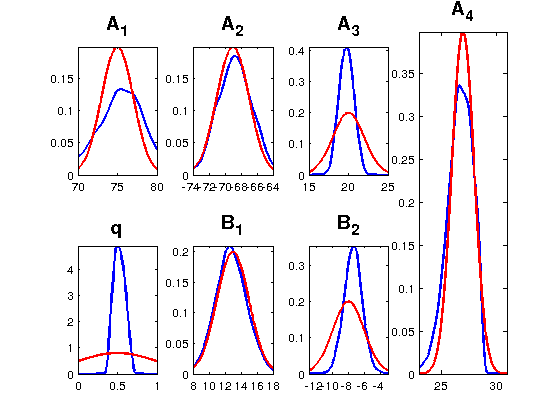

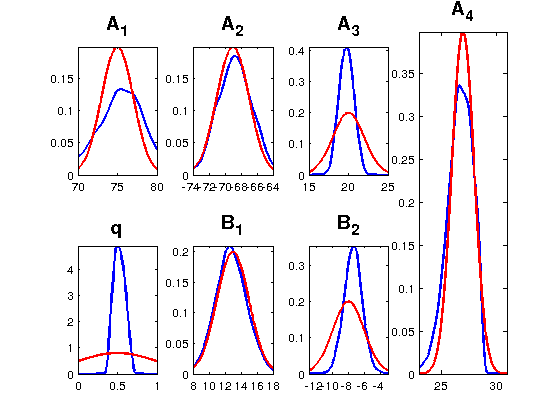

Comparison of the prior (red line) and posterior (blue line) densities for the parameters

of a model for censored metallic fatigue data with nonconstant standard deviation.